Maltose syrup vs glucose syrup and its uses

2018-12-19 / Industry newsGlucose syrup refers to syrup for food processing produced by an acid process, maltose syrup refers to ordinary maltose syrup and high maltose syrup produced by enzymatic method; oligosaccharide syrup refers to malt oligosaccharide syrup produced by enzymatic method and different Malt oligosaccharide pulp.

The maltose syrup vs glucose syrup same points:

1. Both are production from starch or starchy raw materials, can be called starch syrup;

2. Widely used in food processing industries such as candy, biscuits, cakes, beverages, cold drinks and dairy products;

3. The quality of syrup is represented by physical and chemical indicators: sugar component, DE value, moisture, sweetness, viscosity, sugar temperature, solubility, pH, color, light transmittance, etc.;

4. The food safety requirements and health indicators of maltose syrup and glucose syrup prescribed by the state are the same.

Packaged maltose syrup

Packaged maltose syrup

The difference between maltose syrup vs glucose syrup:

1. Different production processe: Glucose syrup is produced by using hydrochloric acid or sulfuric acid as a catalyst; maltose syrup and oligosaccharide syrup are produced by using an enzyme preparation as a biocatalyst. Whether it is syrup using acid or enzymatic process, the production process uses acid or enzyme preparations in different varieties, dosages, production conditions and reaction time, and the products produced are different. In other words, the production process of various syrups is different.

2. Maltose syrup vs glucose syrup has different sugar components, and the resulting syrup has different physical and chemical properties. The sugar component of the syrup not only directly determines the DE value (ie, the amount of reducing sugar) but more importantly determines the sweetness, viscosity, solubility, sugar temperature, browning reaction, fragrance retention, anti-crystallization, and temperature absorption of the syrup. A range of physicochemical properties such as heat retention and fermentability.

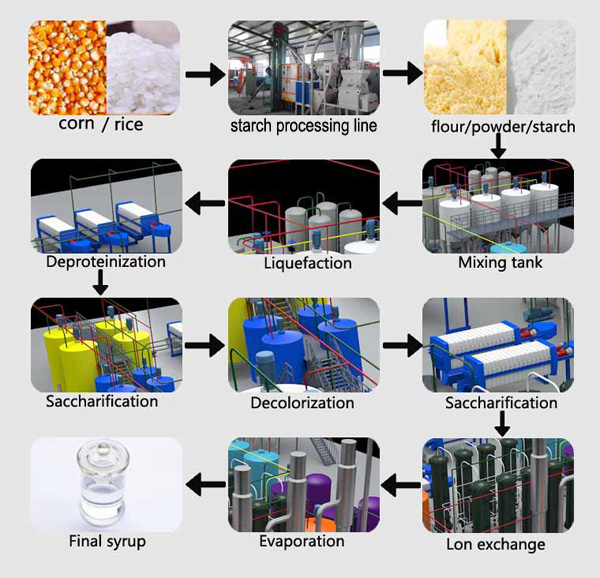

Starch syrup processing equipment

Starch syrup processing equipment

The biggest difference between glucose syrup, maltose syrup and oligosaccharide is not in their respective production processes. In fact, with the development of new varieties of enzyme preparations and the improvement of people's application technology, many syrups now can be produced by enzymatic process and can reach various quality indicators. The biggest and most fundamental difference between maltose syrup and glucose syrup is that they have different syrup sugar components.

The sugar component of the glucose syrup is generally rich in glucose, and components such as glucose (G1), maltose (G2), maltotriose (G3), and maltotetraose (G4) are decreased in a certain proportion. The sugar component of maltose syrup is mainly maltose, with the least amount of glucose, and the total content of G3+G4+G5 is more. The total amount of oligosaccharides (G2+G3+G4+G5) in the sugar component of malt oligosaccharide pulp is 60-70%, or even more, and glucose is rare. The isomalto-oligosaccharide pulp is mainly composed of functional oligosaccharides such as isomaltose, panose, isomaltotriose and isomaltotetraose. Some varieties also use high-tech separation technology to remove glucose, so that the total content of multifunctional oligosaccharides is more than 90%. The sugar components of these syrups form the physicochemical properties of syrups, making them widely available in food production such as confectionery, biscuits, and pastries.

Syrup processing machine

Syrup processing machine

Maltose syrup and glucose syrup uses according to their features:

Before the maltose syrup and oligosaccharide pulp were produced, the syrup used in the food industry was glucose syrup. Therefore, in people's experience and books, it is believed that the syrup DE value determines the nature of the syrup. In fact, the same DE value of the syrup, their sugar components can be different. For example, a syrup with a DE value of 26, a component of an acid syrup: G1:18%. G2-G7 totaled 38%, and G8 and above (dextrin) totaled 54%. The components of the enzymatic syrup: G1: 5%, G2-G7 total 68%, and G8 and above (dextrin) total 27%. The performance of these two syrups is completely different. The latter can be used to produce high-grade coke-flavored hard candy, the former can not.

Another example is the DE value of 42 syrup, the composition of the acid syrup: G1:19.3%, G2: 14.3%, G3: 11.8%. G4 and above totaled 54.6%. The components of the enzymatic syrup: G1: 0.8%, G2: 48.2%, G3: 17.6%, and G4 and above totaled 33.4%. The use of these two syrups is different. The former can only produce ordinary hard candy, and the shelf life is not long. The latter can be used to produce high-quality confectionery, which can also be used to produce high-grade brittle biscuits. The structure of the syrup component determines the characteristics and use value of the syrup, and the comprehensive utilization of the syrup characteristics creates the excellent quality and brand characteristics of various foods.

Syrup production process

Syrup production process

Maltose syrup vs glucose syrup sugar component and syrup characteristics:

The sugar component of the maltose syrup vs glucose syrup refers to the percentage of sugar such as glucose, maltose, maltotriose, maltotetraose, etc., which is also called component structure. Different varieties and specifications of foods require different quality syrups. Mastering the functional effects of syrup sugar components on foods and meeting the technological requirements in food production is mainly by their characteristics.

The sugar component is the product of starch hydrolysis, as the degree of hydrolysis continues to deepen. Starch is hydrolyzed to dextrin during liquefaction, and oligosaccharides (G7, G6, G5, G4, G3) maltose (G2) hydrolyzed from dextrin (G8 and above) to glucose (G1) during saccharification. The molecular weight is getting smaller and smaller, the molecular structure is complicated to simpler, and the characteristics of the sugar component are regularly changed.

Syrup characteritics influenced by hydrolysis:

Sweetness: increased with the degree of hydrolysis

Viscosity: decreases with the degree of hydrolysis

Thermal stability: increased with the degree of hydrolysis

Resistance to crystallinity: decreased with the degree of hydrolysis

Solubility: increases with the degree of hydrolysis

Osmotic pressure: increased with the degree of hydrolysis

Moisture activity: reduced with the degree of hydrolysis

Browning reaction: increase with the degree of hydrolysis

Perfuming ability: reduced with the degree of hydrolysis

Fermentation capacity: increases with the degree of hydrolysis

Syrup processing plant

Syrup processing plant

In addition to the above 10 regularity characteristics, there are some specialities under the general trend. For example, the temperature of sugar is higher than that of maltose.

In the hygroscopicity (water vapor absorption) of sugar, usually G3>G4>G5=G7>G1>G2, maltotriose has the highest hygroscopicity and maltose is the lowest. In the moisturizing (water-holding, binding to moisture) oligosaccharides (G3-G7), the moisture retention is relatively high, and G2>G1. Glucose is highly vapor-absorbent and has poor water holding capacity. In confectionery production, we often find that candy with high glucose content will be "watery" sticky, so-called "confectionery hairpin". The confectionery or food produced by the malt oligosaccharide pulp is controlled by the relative humidity of the production workshop and immediately sealed after cooling, and the hygroscopicity of the oligosaccharide is easily solved.

In the production of cakes, the moisture retention of oligosaccharides is fully utilized, and the problem of starch aging is satisfactorily solved by the joint efforts of oligosaccharides and emulsifiers. The moisturizing malt oligosaccharide or isomalto-oligosaccharide is used. Under the action of the emulsifier, the oil and water are blended and fully emulsified and never separated. The moisture of the food is kept, and the taste is soft and sweet.

Raw materials for biscuits: sugar, flour, oil and food additives. For the sugar required for biscuit production, the first consideration is starch syrup. The choice of syrup should meet the quality characteristics of biscuits. Comprehensive requirements for scent characteristics and preservation capacity; secondly, adaptability and operability to production equipment and processes; finally consider the impact of syrup price on product production cost and competitiveness.

Biscuits made with syrup

Biscuits made with syrup

Current biscuit production mainly consists of brittle biscuits, tough biscuits and cake products. Glucose syrup is relatively inexpensive, but its sugar composition and quality may not meet the current level of biscuit quality. Therefore, the syrups suitable for the production of biscuits are mainly high maltose syrup and malt oligosaccharide pulp, and in the production of brittle biscuits, the syrup used is high maltose syrup.

High maltose syrup is used in the production of brittle sweet biscuits. The syrup is not bleached or discolored according to customer requirements. The syrup contains soluble protein, amino acids and a small amount of calcium and magnesium ions, which will aggravate the Maillard reaction, and the color is beautiful and fragrant. In the past, sugar was produced from malt or bran, and non-marked sugar was the best raw material for producing brittle biscuits.

From above, you can see that the enzyme hydrolysis starch has been a more popular choice with high quality starch syrup processing. In the syrup production process, the key to the technology is to control the sugar component. When saccharifying with fungal alpha-amylase, do not over-sweet. Because the fungal α-amylase saccharification mechanism is to produce maltotriose first, then the maltose content gradually increases, to master the timely termination of the reaction. In order to control the proportion of components of each sugar. This syrup can also be produced using the maltose production enzyme Maltogenase, but at a higher production cost.