How converting corn starch into corn syrup ?

2018-07-03 / FAQ

All kinds of starch syrup can be got by corn starch hydrolysis with acid or enzyme, the liquid products are maltose, glucose, fructose syrup. However, the enzyme method for starch hydrolysis is more convenient with good economic benefit for converting corn starch into corn syrup, also can make a high quality corn syrup, usually glucose, different enzyme adopted can converting different type syrup. Acid is corrosive, if you want to use acid method for converting corn starch into corn syrup, that means your syrup equipments must higher requests and the service life is not long, this is not necessary, so Doing Company suggest you adopt the enzyme method to converting corn starch into corn syrup.

How converting corn starch into corn syrup ?

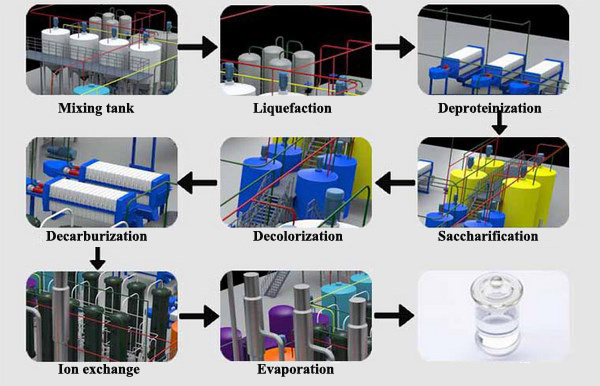

Process for converting corn starch into corn syrup

Below is the introduction of each process:

(1) Corn starch milk adjustment: The DS value of the starch that came from starch plant is adjusted to 28-32% and control a proper value of PH and temperature. Or adding a certain amount of water to achieve the above conditions then go to the next section.

(2) Liquefaction: Starch milk is sent to buffer tank then liquefied by jet cooker with the aid of enzyme.

(3) Residue separation and drying: The liquefied material goes to filter press machinery for separating protein. Then using the process water wash the residue to recover glucose. After washing, the residue is sent to bundle dryer machine for dreg drying. After this process used for converting corn starch into corn syrup, we can get a protein cake, which is a good animal feed.

DOING filter press

(4) Saccharification: The liquefied material keeps reaction for a certain time under the action of enzyme. The required DE value of the glucose will be produced. Then the material is sent to the enzyme killer to kill the enzyme, and the saccharification liquid yield is about 98%-105% in the converting corn starch into corn syrup process.

(5) Filtration and decolorization: Glucose gets through the filter to remove protein and other impurities, then at the appropriate temperature passes by active carbon to decoloring, finally send to filters to remove activated carbon and send to the next section. The filteration process to converting corn starch into corn syrup usually adopt the plate frame filter press machine.

Main machine used for corn syrup production

(6) Ion exchanger: Tiny foreign items and bad odor is removed via ion exchanger then we can get high quality glucose, after this process, the glucose is pure can be eaten.

(7) Evaporation: The glucose is totally cleaned through safety filter machine then sent to DOING professional syrup evaporator for concentrating to reach the required DS as final product. The final dry substance content is adjusted to the market demand, or to the subsequent processing steps.

One of our installed corn syrup production plant

To sum up, among is the brief description for how converting corn starch into corn syrup, main machine adopted is mixing tank, jet cooker, liquefaction tank, filter press, saccharification tank, ion exchange column, evaporator. Also the auxiliary equipment like flash tank, heat exchanger, PH adjust tank, etc. We can supply the technology data and all equipments for you to converting corn starch into corn syrup, if you want to get fructose, we also can offer you the isomerism process requests technology data and machine.

How converting corn starch into corn syrup ?

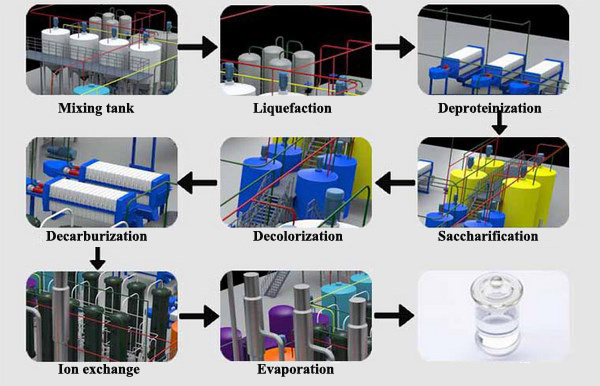

Process for converting corn starch into corn syrup

(1) Corn starch milk adjustment: The DS value of the starch that came from starch plant is adjusted to 28-32% and control a proper value of PH and temperature. Or adding a certain amount of water to achieve the above conditions then go to the next section.

(2) Liquefaction: Starch milk is sent to buffer tank then liquefied by jet cooker with the aid of enzyme.

(3) Residue separation and drying: The liquefied material goes to filter press machinery for separating protein. Then using the process water wash the residue to recover glucose. After washing, the residue is sent to bundle dryer machine for dreg drying. After this process used for converting corn starch into corn syrup, we can get a protein cake, which is a good animal feed.

DOING filter press

(4) Saccharification: The liquefied material keeps reaction for a certain time under the action of enzyme. The required DE value of the glucose will be produced. Then the material is sent to the enzyme killer to kill the enzyme, and the saccharification liquid yield is about 98%-105% in the converting corn starch into corn syrup process.

(5) Filtration and decolorization: Glucose gets through the filter to remove protein and other impurities, then at the appropriate temperature passes by active carbon to decoloring, finally send to filters to remove activated carbon and send to the next section. The filteration process to converting corn starch into corn syrup usually adopt the plate frame filter press machine.

Main machine used for corn syrup production

(6) Ion exchanger: Tiny foreign items and bad odor is removed via ion exchanger then we can get high quality glucose, after this process, the glucose is pure can be eaten.

(7) Evaporation: The glucose is totally cleaned through safety filter machine then sent to DOING professional syrup evaporator for concentrating to reach the required DS as final product. The final dry substance content is adjusted to the market demand, or to the subsequent processing steps.

One of our installed corn syrup production plant

To sum up, among is the brief description for how converting corn starch into corn syrup, main machine adopted is mixing tank, jet cooker, liquefaction tank, filter press, saccharification tank, ion exchange column, evaporator. Also the auxiliary equipment like flash tank, heat exchanger, PH adjust tank, etc. We can supply the technology data and all equipments for you to converting corn starch into corn syrup, if you want to get fructose, we also can offer you the isomerism process requests technology data and machine.