High maltose syrup process

2018-08-23 / FAQ

The high maltose syrup process by using β-amylase or fungal α-amylase, glucose syrups containing over 50% maltose, or even over 70% maltose (extra-high-maltose syrup) can be produced. This is possible because these enzymes remove two glucose units, that is, one maltose molecule at a time from the end of the starch molecule.

High maltose syrup process details description:

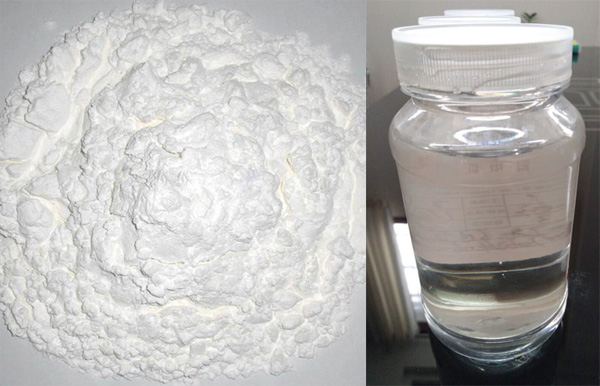

(1) Starch milk adjustment: The raw material of high maltose syrup process is different kinds of starch or starch milk.

The DS value of the starch that came from starch plant is adjusted to 28-32% and control a proper value of PH and temperature. Or adding a certain amount of water to achieve the above conditions then go to the next section.

High maltose syrup process parts

(2) Liquefaction: Starch milk is sent to buffer tank then liquefied by jet cooker with the aid of enzyme.

During high maltose syrup processing, liquifaction is a very important role when corn starch syrup processing.

Put the starch slurry into the mixing tank. Sometimes you will find mixing tank surface with brown floater, it is likely to be excessively high protein content. It will cause high dosage of activated carbon, increasing the load of ion exchange, and reducing the service life of ion-exchange resin, so we must ensure that the starch milk protein content is below 0.5%.

(3) Saccharification: It is also a important step during the high maltose syrup processing. The liquefied material keeps reaction for a certain time under the action of enzyme. The required DE value of the glucose will be produced. Then the material is sent to the enzyme killer to kill the enzyme.

High maltose syrup

(4) Filtration and decolorization: Glucose gets through the filter to remove protein and other impurities, then at the appropriate temperature passes by active carbon to decoloring, finally send to filters to remove activated carbon and send to the next section.

During the high maltose syrup process decolorization process, the normal sequence is: The first decolorization-the first decarburization-The second decolorization-the second decarburization.

High maltose syrup process decolorization process details description: the saccharogenic liquid will be pumped into a decolorization tank, add the waste activated carbon of the second plate frame filter pressing then killing enzyme and decolorization for 30 minutes. Then pumping the discolored syrup liquid into the first plate frame, the activated carbon will be filter out.

Pumping the first discolored syrup liquid into the second decolorization tank, adding new activated carbon, decolorization for 30 minutes.

The second decolored syrup liquid is subjected to plate and frame filtration, and then it will be pumped into the ion exchange system storage tank through the plate heat exchanger.

Maltose syrup production equipment

(5) Evaporation for high maltose syrup process: The glucose is totally cleaned through safety filter machine then sent to evaporator for concentrating to reach the required DS as final product. According to different requirement of High fructose syrup process plant,we match different eveaporators

(6) Isomerism: this process function is change the glucose into fructose. More changed percentage, more sweetness.

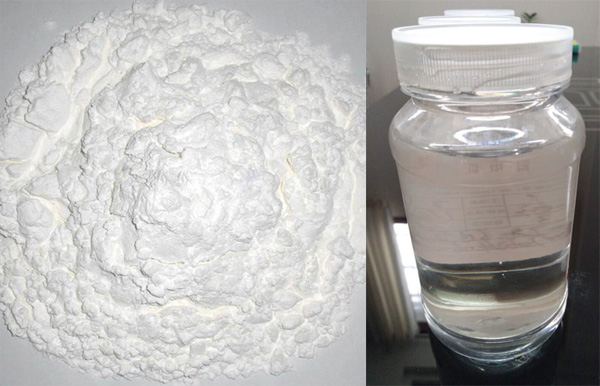

(7) High maltose syrup refining process: the isomerized raw syrup was prepared by the secondary decoloration and the secondary concentration process. After adjusting the temperature, it was pumped into the special tank for storage, which was the finished product high maltose syrup.

High-maltose syrup is a food additive used as a sweetener and preservative. The majority sugar is maltose. It is less sweet than high-fructose corn syrup and contains little to no fructose. It is sweet enough to be useful as a sweetener in commercial food production, however.To be given the label "high", the syrup must contain at least 50% maltose. Typically, it contains 40–50% maltose, though some have as high as 70%.

Besides the high maltose syrup process machine, Our company also offer the turn-key project services, inclduing the technical consulting service, manufacturing high maltose syrup process machine, installation of high maltose syrup process machine, commissioning of fructose syrup preparation machine etc.

High maltose syrup process details description:

(1) Starch milk adjustment: The raw material of high maltose syrup process is different kinds of starch or starch milk.

The DS value of the starch that came from starch plant is adjusted to 28-32% and control a proper value of PH and temperature. Or adding a certain amount of water to achieve the above conditions then go to the next section.

High maltose syrup process parts

During high maltose syrup processing, liquifaction is a very important role when corn starch syrup processing.

Put the starch slurry into the mixing tank. Sometimes you will find mixing tank surface with brown floater, it is likely to be excessively high protein content. It will cause high dosage of activated carbon, increasing the load of ion exchange, and reducing the service life of ion-exchange resin, so we must ensure that the starch milk protein content is below 0.5%.

(3) Saccharification: It is also a important step during the high maltose syrup processing. The liquefied material keeps reaction for a certain time under the action of enzyme. The required DE value of the glucose will be produced. Then the material is sent to the enzyme killer to kill the enzyme.

High maltose syrup

(4) Filtration and decolorization: Glucose gets through the filter to remove protein and other impurities, then at the appropriate temperature passes by active carbon to decoloring, finally send to filters to remove activated carbon and send to the next section.

During the high maltose syrup process decolorization process, the normal sequence is: The first decolorization-the first decarburization-The second decolorization-the second decarburization.

High maltose syrup process decolorization process details description: the saccharogenic liquid will be pumped into a decolorization tank, add the waste activated carbon of the second plate frame filter pressing then killing enzyme and decolorization for 30 minutes. Then pumping the discolored syrup liquid into the first plate frame, the activated carbon will be filter out.

Pumping the first discolored syrup liquid into the second decolorization tank, adding new activated carbon, decolorization for 30 minutes.

The second decolored syrup liquid is subjected to plate and frame filtration, and then it will be pumped into the ion exchange system storage tank through the plate heat exchanger.

Maltose syrup production equipment

(5) Evaporation for high maltose syrup process: The glucose is totally cleaned through safety filter machine then sent to evaporator for concentrating to reach the required DS as final product. According to different requirement of High fructose syrup process plant,we match different eveaporators

(6) Isomerism: this process function is change the glucose into fructose. More changed percentage, more sweetness.

(7) High maltose syrup refining process: the isomerized raw syrup was prepared by the secondary decoloration and the secondary concentration process. After adjusting the temperature, it was pumped into the special tank for storage, which was the finished product high maltose syrup.

High-maltose syrup is a food additive used as a sweetener and preservative. The majority sugar is maltose. It is less sweet than high-fructose corn syrup and contains little to no fructose. It is sweet enough to be useful as a sweetener in commercial food production, however.To be given the label "high", the syrup must contain at least 50% maltose. Typically, it contains 40–50% maltose, though some have as high as 70%.

Besides the high maltose syrup process machine, Our company also offer the turn-key project services, inclduing the technical consulting service, manufacturing high maltose syrup process machine, installation of high maltose syrup process machine, commissioning of fructose syrup preparation machine etc.