How is rice syrup made by industry production ?

2018-10-09 / FAQ

About the rice syrup made by industry production, it means that the professional complete set of syrup equipments must be adopted. How is rice syrup made, its industry production process is: rice milling-mixing slurry-jet liquefaction-saccharification-filtration-ion exchange-evaporation. By the way, rice has a lower protein content, so DOING company rice syrup production technology can produce syrup from rice flour/ rice powder directly, no need to extract the starch, also guarantee the produced starch high quality.

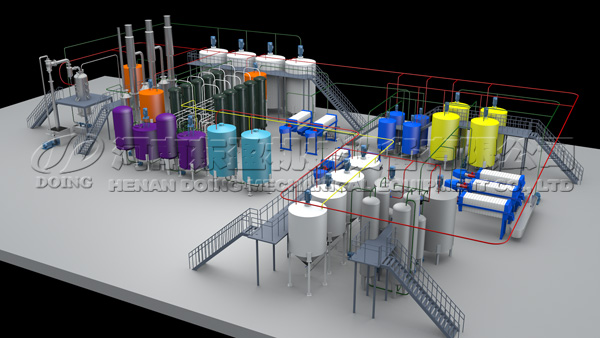

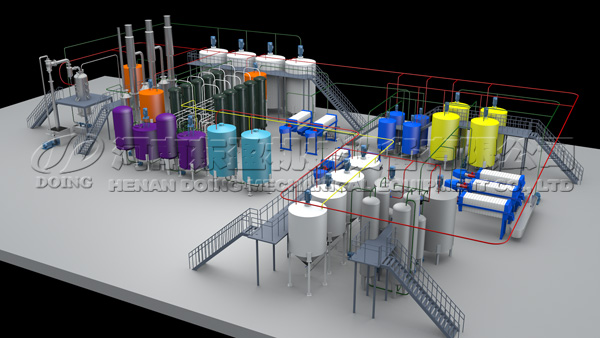

The complete syrup equipments for how is rice syrup made by industry production used include: rice flour processing machine, mixing tank, jet cooker, liquefaction tank, saccharification tank, drum filter, plate frame filter press, ion exhange column, syrup evaporator.

Finished rice syrup

Next, how is rice syrup made by industry production, some details of the process need attention:

1. The ejector must be low pressure, high pressure is unstable, and liquefied is not completely susceptible to bacteria. The liquefaction sequence is preferably first injection - liquefaction - second injection, the liquefaction column is preferably made into a diameter of 800 and a height of 5000, DOING column more slimmer, improve the efficiency in the process of how is rice syrup made by industry production.

2. The saccharification time is at least 18 hours. DOING saccharification tank increased the size so the time cost may be shorter.

3. The process of the filtration section is first deprotein, ion exchange, decolorization, all filter press made by the plates. Waste activated carbon also remove by plate frame filter press machine in the process of how is rice syrup made by industry production.

Syrup equipments

4. The system uses 2 kinds of activated carbon, dry carbon moisture is 10%, wet carbon moisture 50%, is special for how is rice syrup made by industry production, consumption can be controlled to 4 kg / ton of products.

5. Before the ion exchange process of how is rice syrup made by industry production, the storage tank must be large, at least 40 cubic meters, otherwise the process will fluctuate, the PH will change, the color will not be guaranteed, and the resin will also have a special purpose.

6. The rice syrup production line for how is rice syrup made by industry production is 14 valves per column from the column, while the corn syrup is 11-12 per column, this column should be the same.

7. Syrup concentration is best done with 4 effect evaporator, 4-1-2-3 order, combined with single effect syrup evaporator in this process.

8. The finished rice syrup must be stored in a special syrup storage tank to ensure quality and facilitate later packaging and transportation.

The complete syrup equipments for how is rice syrup made by industry production used include: rice flour processing machine, mixing tank, jet cooker, liquefaction tank, saccharification tank, drum filter, plate frame filter press, ion exhange column, syrup evaporator.

Finished rice syrup

1. The ejector must be low pressure, high pressure is unstable, and liquefied is not completely susceptible to bacteria. The liquefaction sequence is preferably first injection - liquefaction - second injection, the liquefaction column is preferably made into a diameter of 800 and a height of 5000, DOING column more slimmer, improve the efficiency in the process of how is rice syrup made by industry production.

2. The saccharification time is at least 18 hours. DOING saccharification tank increased the size so the time cost may be shorter.

3. The process of the filtration section is first deprotein, ion exchange, decolorization, all filter press made by the plates. Waste activated carbon also remove by plate frame filter press machine in the process of how is rice syrup made by industry production.

Syrup equipments

4. The system uses 2 kinds of activated carbon, dry carbon moisture is 10%, wet carbon moisture 50%, is special for how is rice syrup made by industry production, consumption can be controlled to 4 kg / ton of products.

5. Before the ion exchange process of how is rice syrup made by industry production, the storage tank must be large, at least 40 cubic meters, otherwise the process will fluctuate, the PH will change, the color will not be guaranteed, and the resin will also have a special purpose.

6. The rice syrup production line for how is rice syrup made by industry production is 14 valves per column from the column, while the corn syrup is 11-12 per column, this column should be the same.

7. Syrup concentration is best done with 4 effect evaporator, 4-1-2-3 order, combined with single effect syrup evaporator in this process.

8. The finished rice syrup must be stored in a special syrup storage tank to ensure quality and facilitate later packaging and transportation.