Rice malt syrup process

2018-08-10 / FAQ

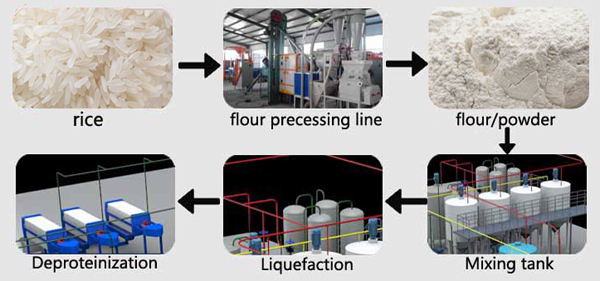

Rice malt syrup is made from 100% organic brown rice. It is made through culturing rice with enzymes to breakdown the starches and then cooking until it becomes syrup. The final product contains soluble complex carbohydrates, maltose and a small amount of glucose. Rice malt syrup is 100% fructose free. It's worth to say that our company rice malt syrup process can use the corn flour to complete, and rice is a most suitable material for malt syrup production, also can used for glucose or fructose syrup production, following will introduce the rice malt syrup process from Doing Company.

Rice maltose syrup processing equipment made by DOING

The rice malt syrup process technology introduction:

Step 1: Wet method to milling rice.

Using wet method to make ric flour firstly.

The features are below :

Rice flour from nine varieties, subjected to dry- and wet-milling processes, was determined for its physical and chemical properties. The results revealed that milling method had an effect on properties of flour. Wet-milling process resulted in flour with significantly lower protein and ash contents and higher carbohydrate content. Wet-milled flour also tended to have lower lipid content and higher amylose content. In addition, wet-milled rice flour contained granules with smaller average size compared to dry-milled samples. Swelling power at 90 °C of wet-milled samples was higher while solubility was significantly lower than those of dry-milled flour. Dry milling process caused the destruction of the crystalline structure and yielded flour with lower crystallinity compared to wet-milling process, which resulted in significantly lower gelatinization enthalpy. So we adopt the wet method to milling rice for rice malt syrup process.

Rice malt syrup process

Step 2.Mixing slurry unit

Put the rice powder and water into the mixing tank, then put in enzyme, keep on particular standard temperature, waiting for some time , then can transport to next work section for rice malt syrup process.

Step 3.Injector liquefaction unit

The mixed rice pwoder milk is sent to buffer tank in rice malt syrup process then liquefied by jet cooker with the aid of enzyme at high temperature in regular time .

Step 4. Filter press deproteinization unit

Because of inside of the rice slurry have too much protein, so the slurry need pumping into the press filter, after press the slurry, the syrup will flow into the slot, the protein will stay inside the filter machine, then complete the deproteinization in rice malt syrup process.

Rice malt syrup process

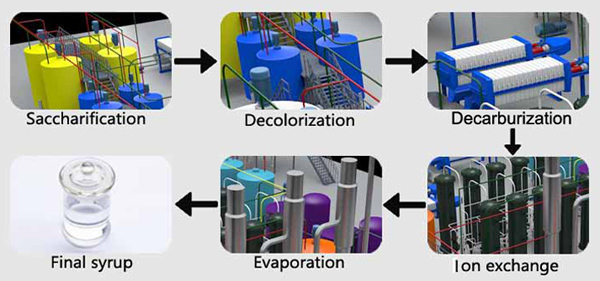

Step 5.Saccharification unit

The liquefied material is sent to enzyme saccharification tank for reaction. Maintain at specific temperature for some time, the syrup will transfer to maltose syrup .

Step 6.Decolorization unit

After LAB testing for rice malt syrup process, all the maltose syrup pumping into the decoloration tanks, at uniform temperature, mix with activated carbon, usually it have to make twice to get pure maltose syrup.

Rice malt syrup proocessing plant design

Step 7.Filter press decarburization unit

The maltose syrup with activated carbon will be pumped into the press filter which is an important equipment for rice malt syrup process, after press the clean maltose syrup will flow into the buffer tank, the activated carbon will stay inside the filter.

Step 8.Ion exchange unit

The clean maltose syrup pumping into the ion exchange columns, inside the column resin will attract all the cation and anion and other small electron, then will get very pure glucose syrup for people eating. This equipment always is used for high quality product rice malt syrup process.

Rice malt syrup processing equipment

Step 9.Concentration unit

Under vacuum conditions in rice malt syrup process, the maltose syrup is heated for evaporation. When the maltose syrup concentration reaches the technology requirement, then it cools the temperature and enters into the final product tank for storage. The finished product can be high maltose syrup and super high maltose syrup .

Above all is the simple description for rice malt syrup process technology intrduction,we are the professional rice malt syrup process equipment manufacturer,and we can provide you the feasibility program according to your demand for rice malt syrup process equipment.

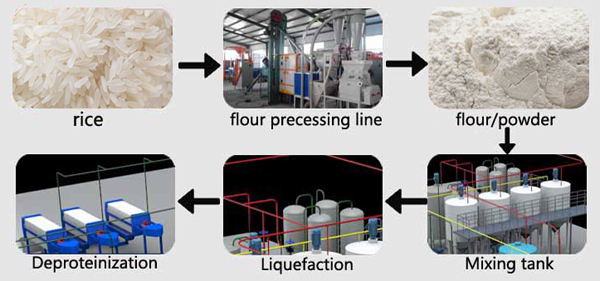

Rice maltose syrup processing equipment made by DOING

Step 1: Wet method to milling rice.

Using wet method to make ric flour firstly.

The features are below :

Rice flour from nine varieties, subjected to dry- and wet-milling processes, was determined for its physical and chemical properties. The results revealed that milling method had an effect on properties of flour. Wet-milling process resulted in flour with significantly lower protein and ash contents and higher carbohydrate content. Wet-milled flour also tended to have lower lipid content and higher amylose content. In addition, wet-milled rice flour contained granules with smaller average size compared to dry-milled samples. Swelling power at 90 °C of wet-milled samples was higher while solubility was significantly lower than those of dry-milled flour. Dry milling process caused the destruction of the crystalline structure and yielded flour with lower crystallinity compared to wet-milling process, which resulted in significantly lower gelatinization enthalpy. So we adopt the wet method to milling rice for rice malt syrup process.

Rice malt syrup process

Put the rice powder and water into the mixing tank, then put in enzyme, keep on particular standard temperature, waiting for some time , then can transport to next work section for rice malt syrup process.

Step 3.Injector liquefaction unit

The mixed rice pwoder milk is sent to buffer tank in rice malt syrup process then liquefied by jet cooker with the aid of enzyme at high temperature in regular time .

Step 4. Filter press deproteinization unit

Because of inside of the rice slurry have too much protein, so the slurry need pumping into the press filter, after press the slurry, the syrup will flow into the slot, the protein will stay inside the filter machine, then complete the deproteinization in rice malt syrup process.

Rice malt syrup process

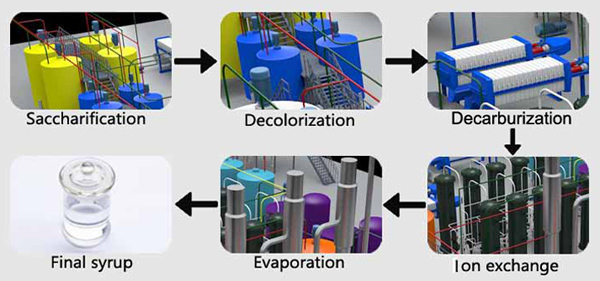

Step 5.Saccharification unit

The liquefied material is sent to enzyme saccharification tank for reaction. Maintain at specific temperature for some time, the syrup will transfer to maltose syrup .

Step 6.Decolorization unit

After LAB testing for rice malt syrup process, all the maltose syrup pumping into the decoloration tanks, at uniform temperature, mix with activated carbon, usually it have to make twice to get pure maltose syrup.

Rice malt syrup proocessing plant design

Step 7.Filter press decarburization unit

The maltose syrup with activated carbon will be pumped into the press filter which is an important equipment for rice malt syrup process, after press the clean maltose syrup will flow into the buffer tank, the activated carbon will stay inside the filter.

The clean maltose syrup pumping into the ion exchange columns, inside the column resin will attract all the cation and anion and other small electron, then will get very pure glucose syrup for people eating. This equipment always is used for high quality product rice malt syrup process.

Rice malt syrup processing equipment

Under vacuum conditions in rice malt syrup process, the maltose syrup is heated for evaporation. When the maltose syrup concentration reaches the technology requirement, then it cools the temperature and enters into the final product tank for storage. The finished product can be high maltose syrup and super high maltose syrup .

Above all is the simple description for rice malt syrup process technology intrduction,we are the professional rice malt syrup process equipment manufacturer,and we can provide you the feasibility program according to your demand for rice malt syrup process equipment.