Which company makes syrup equipment ?

2018-03-08 / FAQ

Doing company have three factory, we are a professional syrup equipment supplier in China. Following is the introduction of our syrup equipment.

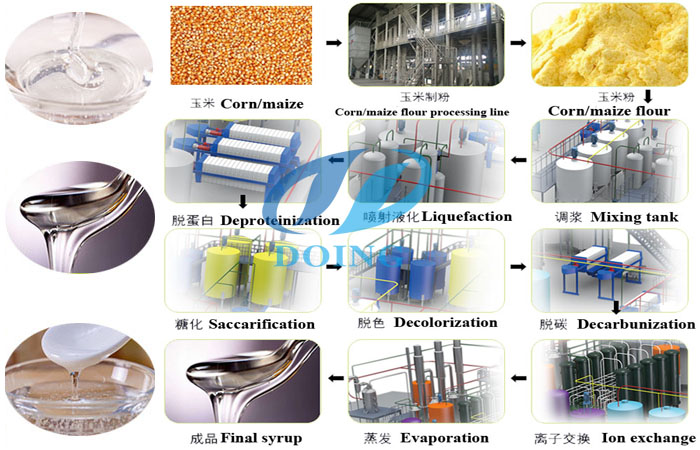

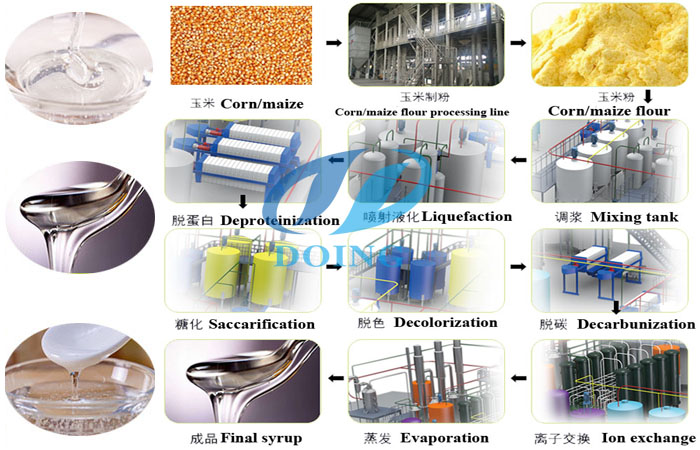

Below is process of liquid corn syrup production equipment, and contains all the liquid corn syrup production equipment during the liquid corn syrup production equipment:

Corn directly make syrup equipment process

The old technolgy of liquid corn syrup production equipment is using the corn starch as material, the newest technology of liquid corn syrup production equipment can use the corn as raw material,no need convert starch firslty, then been corn syrup, can be took of sryup from corns or maize.

Mixing slurry section of syrup production

2. Continuous spray liquefaction section during the liquid corn syrup production equipment

(1) Mixing slurry: Add thermostable amylase and water to flour, and mix them in mixing slurry tank

(2) Spray liquefaction: Heating all tanks by steam, then start Liquid ejectors and pumps. Delivery material continuously and evenly, and control flow by production capacity.

Flash evaporate material in Laminar flow tank, and keep temperature. Observe liquefaction effect.

(3) High temperature treatment: Send passed material to the second Liquid ejector, and keep temperature.

(4) Carry slurry to buffer tank by pump.

Injector liquefaction of syrup production

Press filter deproteinization syrup production

Saccharification of syrup production

Decoloration section of syrup production

Evaporation section of syrup production

Final glucose syrup storage

Below is process of liquid corn syrup production equipment, and contains all the liquid corn syrup production equipment during the liquid corn syrup production equipment:

Corn directly make syrup equipment process

The old technolgy of liquid corn syrup production equipment is using the corn starch as material, the newest technology of liquid corn syrup production equipment can use the corn as raw material,no need convert starch firslty, then been corn syrup, can be took of sryup from corns or maize.

Mixing slurry section of syrup production

2. Continuous spray liquefaction section during the liquid corn syrup production equipment

(1) Mixing slurry: Add thermostable amylase and water to flour, and mix them in mixing slurry tank

(2) Spray liquefaction: Heating all tanks by steam, then start Liquid ejectors and pumps. Delivery material continuously and evenly, and control flow by production capacity.

Flash evaporate material in Laminar flow tank, and keep temperature. Observe liquefaction effect.

(3) High temperature treatment: Send passed material to the second Liquid ejector, and keep temperature.

(4) Carry slurry to buffer tank by pump.

Injector liquefaction of syrup production

3. Filtration section during the liquid corn syrup production equipment

(1) Filter protein and slag by Plate-and-frame filter press machine.

(2) Carry away protein and slag by Bottom slot for Plate-and-frame filter press machine.

(3) Syrup inflow buffer tanks, then be sent to next step by pump.

(1) Filter protein and slag by Plate-and-frame filter press machine.

(2) Carry away protein and slag by Bottom slot for Plate-and-frame filter press machine.

(3) Syrup inflow buffer tanks, then be sent to next step by pump.

Press filter deproteinization syrup production

4. Saccharification section during the liquid corn syrup production equipment

Cooling syrup by Heat-exchanger, then send them to Saccharification tank (mixer and coil pipe are set in Saccharification tank. ) by Pumps., then add glucoamylase.

Cooling syrup by Heat-exchanger, then send them to Saccharification tank (mixer and coil pipe are set in Saccharification tank. ) by Pumps., then add glucoamylase.

Saccharification of syrup production

5.Decolorization during the liquid corn syrup production equipmen

Carry passed syrup into Decolorization tanks(mixer and coil pipe are set in Saccharification tank.) by pump. Decolor by Activated carbon

Carry passed syrup into Decolorization tanks(mixer and coil pipe are set in Saccharification tank.) by pump. Decolor by Activated carbon

Decoloration section of syrup production

6. Filtration section during the liquid corn syrup production equipment

(1) Filter protein and Activated carbon by Plate-and-frame filter press machine.

(2) Carry away protein by Bottom slot for Plate-and-frame filter press machine

(3) Unclean syrup is sent to big buffer tanks by pump.

(4) Carry clean syrup into buffer tanks.

(1) Filter protein and Activated carbon by Plate-and-frame filter press machine.

(2) Carry away protein by Bottom slot for Plate-and-frame filter press machine

(3) Unclean syrup is sent to big buffer tanks by pump.

(4) Carry clean syrup into buffer tanks.

Ion exchange process

7. Ion exchange section during the liquid corn syrup production equipment

(1) Carry syrup into Ion exchange columns. Resin clean syrup in Ion exchange columns. Then carry clean syrup into buffer tanks.

(2) When Resin loses effect, stop carry syrup into Ion exchange columns, and change another Ion exchange column for work.

(3) Recover Resin: Using heat water to bush resin, then use acid fluid, and alkali fluid to bush Ion exchange columns till Resin has function.

(1) Carry syrup into Ion exchange columns. Resin clean syrup in Ion exchange columns. Then carry clean syrup into buffer tanks.

(2) When Resin loses effect, stop carry syrup into Ion exchange columns, and change another Ion exchange column for work.

(3) Recover Resin: Using heat water to bush resin, then use acid fluid, and alkali fluid to bush Ion exchange columns till Resin has function.

Evaporation section of syrup production

8. Evaporation section during the liquid corn syrup production equipment

Evaporate syrup by Triple-concentrate of evaporator and Single-concentrate of evaporator. When syrup concentration is OK, shut down steam and stop evaporation. And carry syrup to Final-product storage tanks by Pumps.

Evaporate syrup by Triple-concentrate of evaporator and Single-concentrate of evaporator. When syrup concentration is OK, shut down steam and stop evaporation. And carry syrup to Final-product storage tanks by Pumps.

Final glucose syrup storage

9. Final glucose syrup storage

The glucose syrup which reaches the certain density in the evaporation process will be pumped into final product storage tanks for storage. The final product tank can keep the glucose syrup purity before transportation.

The glucose syrup which reaches the certain density in the evaporation process will be pumped into final product storage tanks for storage. The final product tank can keep the glucose syrup purity before transportation.