Fructose syrup preparation machine

Henan doing company mainly manufacture the cassava/potato starch processing machine, cassava flour processing machine, glucose syrup preparation machine, maltose syrup preparation machine, and fructose syrup preparation machine etc. All kinds of starch sugar will be got by corn starch hydrolysis with acid or enzyme. The liquid products are maltose, glucose syrup, fructose syrup; The solid products are monohydrate dextrose, anhydrous dextrose, crystal fructose, maltodextrin, etc. They are mainly used as a sweetener in food industry. Anhydrous dextrose can be used as medical injection, tablet embedding medium, sweeteners for medicinal syrup.

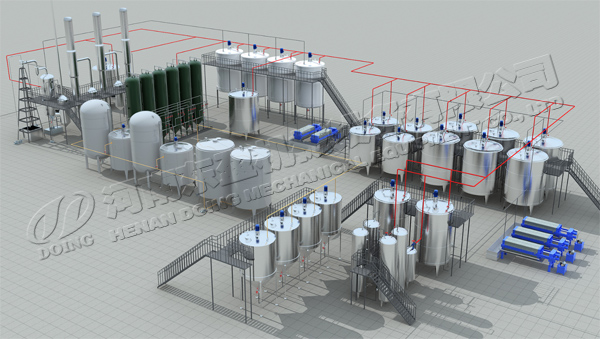

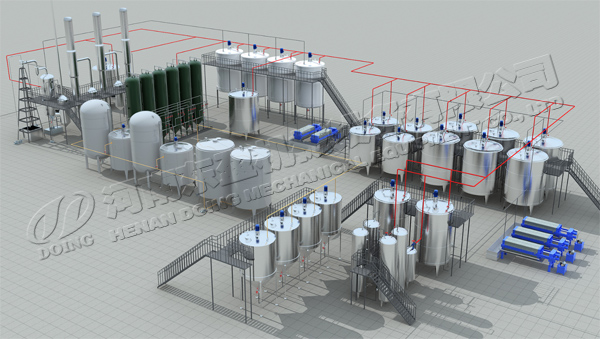

DOING fructose syrup preparation machine design

Below we mainly introduce the fructose syrup processing steps and fructose syrup preparation machine:

Note: the virtual fructose syrup preparation machine model, volume and quantity in order to the production solution to confirm.

Next is the fructose syrup preparation machine process:

(1) Starch milk adjustment: the DS value of the starch that came from starch plant is adjusted to 28-32% and control a proper value of PH and temperature. Or adding a certain amount of water to achieve the above conditions then go to the next section.

(2) Liquefaction: starch milk is sent to buffer tank then liquefied by jet cooker with the aid of enzyme.Used in the liquefaction process can convert the starch into liquid dextrin, the liquefaction tank include the laminar tank, maintaining tank and neutralization tank. The liquid during fructose syrup production pumped by the ejector.

Liquefaction tank

(3) Saccharification of fructose syrup preparation machine: the liquefied material keeps reaction for a certain time under the action of enzyme. The required DE value of the glucose will be produced. Then the material is sent to the enzyme killer to kill the enzyme.

(4) Filtration and decolorization: glucose gets through the syrup filter machine to remove protein and other impurities, then at the appropriate temperature passes by active carbon to decoloring, finally send to filters to remove activated carbon and send to the next section.

(5) Evaporation: the glucose is totally cleaned through safety filter machine then sent to evaporator for concentrating to reach the required DS as final product.

Isomerism system

(6). Isomerism: this isomerism process by fructose syrup preparation machine function is change the glucose into fructose. More changed percentage, more sweetness.

(7). High fructose syrup refining process: the isomerized raw syrup was prepared by the secondary decoloration and the secondary concentration process. After adjusting the temperature, it was pumped into the special tank for storage, which was the finished product F42 high fructose syrup.

Besides the fructose syrup preparation machine and the process introduce, Our company also offer the turn-key project services, inclduing the technical consulting service, manufacturing fructose syrup preparation machine, installation of fructose syrup preparation machine, commissioning of fructose syrup preparation machine etc, Please check the below details:

Fructose syrup preparation machine manufacturered by DOING

1. Complete set energy saving high fructose syrup preparation machine, according to client's different demands offer personal production plan, we will design the most ecnomic benefit and high efficiency technical plan for you.

2. Automatic control system: the advanced nature of control system is the guarantee of high quality products of high fructose syrup production. Continuous and stable production can reduce the production cost.

3. Fructose syrup preparation machine installation, adjust and operation training: all equipments through strict quality testing, after the test passes, Doing Company engineer will adjust the equipments and train the operation people, make sure the production technology reach the requests and your high fructose syrup production operation smoothly.

DOING fructose syrup preparation machine design

| Main machine used for fructose syrup preparation | ||

| Machine | Model/ Volume | Quantity |

| Mixing tank | volume 100L | 2 |

| Liquefaction tank | 24 m3 | 1 |

| Saccharification tank | 200 m3 | 3 |

| Ejector | power 504 kw | 2 |

| Motor | power 840 kw | 1 |

| Isomerism column | volumn 50L | 1 |

| Ion exchange column | 14 | |

| Filter press | 5000L/H | 4 |

| Vacuum cooler | volumn 12 m3 | 1 |

| Liquid-vapor seperator | volumn 12 m3 | 1 |

Note: the virtual fructose syrup preparation machine model, volume and quantity in order to the production solution to confirm.

Next is the fructose syrup preparation machine process:

(1) Starch milk adjustment: the DS value of the starch that came from starch plant is adjusted to 28-32% and control a proper value of PH and temperature. Or adding a certain amount of water to achieve the above conditions then go to the next section.

(2) Liquefaction: starch milk is sent to buffer tank then liquefied by jet cooker with the aid of enzyme.Used in the liquefaction process can convert the starch into liquid dextrin, the liquefaction tank include the laminar tank, maintaining tank and neutralization tank. The liquid during fructose syrup production pumped by the ejector.

Liquefaction tank

(3) Saccharification of fructose syrup preparation machine: the liquefied material keeps reaction for a certain time under the action of enzyme. The required DE value of the glucose will be produced. Then the material is sent to the enzyme killer to kill the enzyme.

(4) Filtration and decolorization: glucose gets through the syrup filter machine to remove protein and other impurities, then at the appropriate temperature passes by active carbon to decoloring, finally send to filters to remove activated carbon and send to the next section.

(5) Evaporation: the glucose is totally cleaned through safety filter machine then sent to evaporator for concentrating to reach the required DS as final product.

Isomerism system

(6). Isomerism: this isomerism process by fructose syrup preparation machine function is change the glucose into fructose. More changed percentage, more sweetness.

(7). High fructose syrup refining process: the isomerized raw syrup was prepared by the secondary decoloration and the secondary concentration process. After adjusting the temperature, it was pumped into the special tank for storage, which was the finished product F42 high fructose syrup.

Besides the fructose syrup preparation machine and the process introduce, Our company also offer the turn-key project services, inclduing the technical consulting service, manufacturing fructose syrup preparation machine, installation of fructose syrup preparation machine, commissioning of fructose syrup preparation machine etc, Please check the below details:

Fructose syrup preparation machine manufacturered by DOING

1. Complete set energy saving high fructose syrup preparation machine, according to client's different demands offer personal production plan, we will design the most ecnomic benefit and high efficiency technical plan for you.

2. Automatic control system: the advanced nature of control system is the guarantee of high quality products of high fructose syrup production. Continuous and stable production can reduce the production cost.

3. Fructose syrup preparation machine installation, adjust and operation training: all equipments through strict quality testing, after the test passes, Doing Company engineer will adjust the equipments and train the operation people, make sure the production technology reach the requests and your high fructose syrup production operation smoothly.