Sugar syrup filter machine

2018-05-22 / Processing

About the sugar syrup filter machine, mainly refer to the plate and frame filter press machine, it's function is to filter the sugar syrup to remove the impurities like protein, fat, fiber and others, for another, also used to the sugar syrup decolorization process, this type sugar syrup filter machine is professional and most suitable one for the syrup production factory. On the following is Doing Company sugar syrup filter machine introduction:

Sugar syrup filter machine used in syrup deproteinization process:

The liquid dextrin which has been through high temperature injection shall move into the plate and frame filter press machine for mechanical extruction. This deproteinization process will seperate the protein and other solid impurities from liquid dextrin by filter press. After that, the liquid dextrin will be pumped to next process, then the protein cake can be left for sale. That's to say our sugar syrup filter machine can give you the add-value in your sugar syrup production factory.

Doing Company sugar syrup filter machine

Sugar syrup filter machine used for the syrup decolorization:

Syrup decolorization process adopted the absorption principle of activated carbon, add the activated carbon with saccharification liquid into a decolorization tank, then filter the waste activated carbon out by the plate and frame filter press machine, generally cost 30 minutes. The syrup decolorization processed by this sugar syrup filter machine normal sequence is the first decolorization-the first decarburization-the second decolorization-the second decarburization. All these section is completed by the plate and frame filter press, it's the best choice for sugar syrup filter. After this, the liquid will be pumped into the ion exchange system storage tank through the plate heat exchanger.

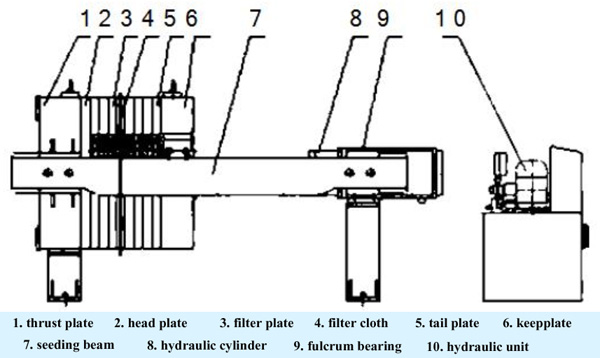

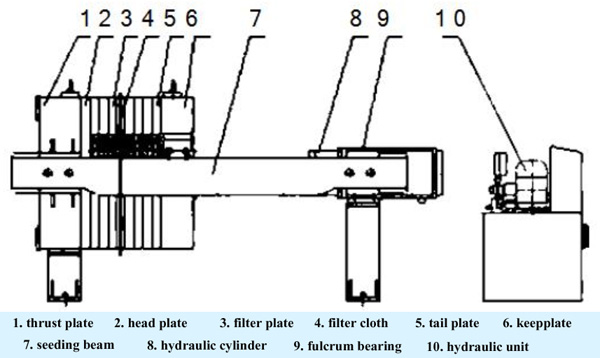

Sugar syrup filter machine structures

Sugar syrup production technology influencing the filter speed and its attention:

1. Water temperature: In the mixing process, must use the warm water, about 50℃, it can improve the liquefaction effect, make fewer particles formed during liquefaction, then improve the filter speed.

2. DE value: Control the DE value in a suitable degree, meke the starch liqufied liquid keep a suitable viscosity, make the filtration work smoothly.

3. PH value: The PH value 4.8-5.0 is best when filtering by our sugar syrup filter machine.

Above all, you have been learned that this sugar syrup filter machine is important for syrup purify.And Doing Company plate and frame filter press machine technical parameters as below:

Doing Company sugar sytup filter machine technical parameters:

Sugar syrup filter machine working principle:

First press the plate frame group by hydraulic force (hydraulic station), and the syrup enters the filter plate from the inlet port of the filter plate. Since both sides of the filter plate are covered with the filter cloth, the platen is pressed by the pressing device. The frame is pressed tightly, that is, a pressure filter room is formed between the plate and the frame, the syrup cannot overflow, the liquid passes through the filter cloth, and is discharged from the lower part of the outlet tank between the filter cloth and the filter plate, and the solid is blocked by the filter cloth in the filter room. When the filter chamber is overfilled, the plate frame is depressurized and the filter plate is pulled apart. The filter cake falls due to gravity and can be pulled away by the car. This sugar syrup filter machine working process consist of the compression plate process, pressure filtration process, filter plate release process and pull plate release process.

Doing Company sugar syrup filter machine(plate and frame filter press machine) with features include: large capacity, long service life, reasonable structure, low noise, small footprint, wide application range, best for sugar syrup production, simple operation, easy maintenance, high degree of automation, smooth operation, low equipment cost, low capital cost. After the filter press, the moisture content of the filter cake is very low, and the artificial demand is small, which greatly saves transportation costs, labor costs, etc.

Sugar syrup filter machine used in syrup deproteinization process:

The liquid dextrin which has been through high temperature injection shall move into the plate and frame filter press machine for mechanical extruction. This deproteinization process will seperate the protein and other solid impurities from liquid dextrin by filter press. After that, the liquid dextrin will be pumped to next process, then the protein cake can be left for sale. That's to say our sugar syrup filter machine can give you the add-value in your sugar syrup production factory.

Doing Company sugar syrup filter machine

Syrup decolorization process adopted the absorption principle of activated carbon, add the activated carbon with saccharification liquid into a decolorization tank, then filter the waste activated carbon out by the plate and frame filter press machine, generally cost 30 minutes. The syrup decolorization processed by this sugar syrup filter machine normal sequence is the first decolorization-the first decarburization-the second decolorization-the second decarburization. All these section is completed by the plate and frame filter press, it's the best choice for sugar syrup filter. After this, the liquid will be pumped into the ion exchange system storage tank through the plate heat exchanger.

Sugar syrup filter machine structures

Sugar syrup production technology influencing the filter speed and its attention:

1. Water temperature: In the mixing process, must use the warm water, about 50℃, it can improve the liquefaction effect, make fewer particles formed during liquefaction, then improve the filter speed.

2. DE value: Control the DE value in a suitable degree, meke the starch liqufied liquid keep a suitable viscosity, make the filtration work smoothly.

3. PH value: The PH value 4.8-5.0 is best when filtering by our sugar syrup filter machine.

Above all, you have been learned that this sugar syrup filter machine is important for syrup purify.And Doing Company plate and frame filter press machine technical parameters as below:

Doing Company sugar sytup filter machine technical parameters:

| Model | Output/m³ | Powder/KW | Remark |

| DY-20 | 80 | 3 | Thermostability polypropylene |

| DY-30 | 100 | 3 | Thermostability polypropylene |

| DY-50 | 120 | 4 | Thermostability polypropylene |

| DY-100 | 150 | 5.5 | Thermostability polypropylene |

Doing Company sugar syrup filter machine

Sugar syrup filter machine working principle:

First press the plate frame group by hydraulic force (hydraulic station), and the syrup enters the filter plate from the inlet port of the filter plate. Since both sides of the filter plate are covered with the filter cloth, the platen is pressed by the pressing device. The frame is pressed tightly, that is, a pressure filter room is formed between the plate and the frame, the syrup cannot overflow, the liquid passes through the filter cloth, and is discharged from the lower part of the outlet tank between the filter cloth and the filter plate, and the solid is blocked by the filter cloth in the filter room. When the filter chamber is overfilled, the plate frame is depressurized and the filter plate is pulled apart. The filter cake falls due to gravity and can be pulled away by the car. This sugar syrup filter machine working process consist of the compression plate process, pressure filtration process, filter plate release process and pull plate release process.

Doing Company sugar syrup filter machine(plate and frame filter press machine) with features include: large capacity, long service life, reasonable structure, low noise, small footprint, wide application range, best for sugar syrup production, simple operation, easy maintenance, high degree of automation, smooth operation, low equipment cost, low capital cost. After the filter press, the moisture content of the filter cake is very low, and the artificial demand is small, which greatly saves transportation costs, labor costs, etc.