What's the process of making corn starch syrup ?

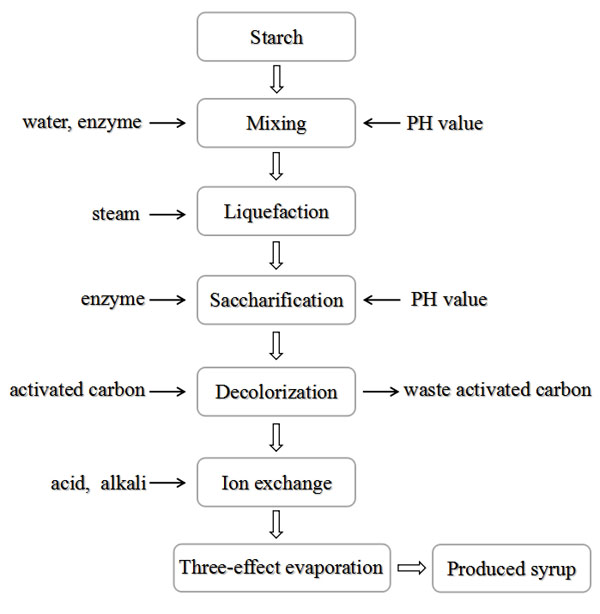

2018-12-03 / FAQThe corn starch syrup is making from high quality corn starch, it is accomplished by enzymatic hydrolysis of the starch. The double enzymatic method is a manufacturing process for hydrolyzing starch into glucose by using a highly specific amylase and saccharifying enzyme as a catalyst. Starch hydrolysis is carried out in two steps: 1. Liquefaction with high temperature resistant a-amylase; 2. Further hydrolysis of the liquefaction solution to glucose with saccharification enzyme. Following flow chart briefly show the corn starch syrup making process:

Corn starch syrup making process

Corn starch syrup making process

What's the process of making corn starch syrup ?

1. Starch mixing

-A. Process description: The main function of this mixing process to making corn starch syrup is to adjust the starch or starch milk to the conditions suitable for liquefaction, and add high temperature liquefaction enzyme to prepare for spray liquefaction.

-B. Process parameters:

a. Baume degree controlled at 16-180 Be (maltose content > 50%); 14-16 Be (maltose content > 70%);

b. The pH of the slurry is controlled between 5.6 and 6.0.

-C. Quality requirements:

a. The raw material has no mildew and no agglomeration;

b. Mixing well and full, no dough or dead ends, the concentration of the liquid should be within the specified range.

Corn syrup processing machine

Corn syrup processing machine

2. High temperature liquefaction

-A. Process description: The adjusted starch milk is fully contacted with steam through the injection port, rapidly heats up, the starch chain is opened, the starch is fully liquefied, and the liquefied enzyme is inactivated by a high temperature and high pressure jet.

-B. Process parameters:

a. the first time injection temperature 103 ± 5 ° C;

b. laminar flow time 50-90min (maltose content > 50%); 40-90min (maltose content > 70%);

c. The secondary injection temperature is 125 ° C -135 ° C in the process of making corn starch syrup.

-C. Quality requirements:

a. The liquefaction liquid DE value is 5-12% (50% maltose content product); the DE value is controlled at 3-7% (70% maltose content product).

Saccharification tank

Saccharification tank

3. Saccharification

-A. Process Description: Using the action of saccharification enzyme, the opened starch chain is cut into the target sugar to a predetermined content.

-B. Process parameters

a. pH value is 5.20-5.55;

b. Saccharification temperature 57 ± 1 °C.

-C. Quality requirements:

a. The maltose content meets the predetermined requirements (content >50% or >70%) for the process of making corn starch syrup;

b. Maltitol special product glucose content <3%; other specifications are implemented according to national standards.

c. The final sugar liquid mix with iodine will be bright yellow.

Syrup processing equipment

Syrup processing equipment

4. Decolorization

-A. Process description: The function of activated carbon and flocculant is used to effectively remove the protein, fat and a small amount of pigment in the product, so that the sugar liquid is clear and translucent.

-B. Process parameters:

a. Addition of activated carbon: the first three batches of 10 kg / batch, flocculant K01: 1kg / batch, flocculant K02: 70g / batch; after three batches, halved.

b. Decolorization temperature 80 ° C ± 1;

c. Add activated carbon first, then add flocculant, stir evenly and let stand for 20-30min.

-C. Quality requirements:

a. Protein, fat, etc. are fully settled;

b. The iodine reaction is bright yellow.

Plate frame filter press

Plate frame filter press

5. Filter process in the process of making corn starch syrup

-A. Process Description: The activated carbon and its floc in the feed liquid are removed by filtration through a plate frame.

-B. Quality requirements:

a. The iodine reaction of the filtrate is bright yellow;

b. The filtrate is clear, no residue, no odor, no acidity.

6. Ion exchange

-A. Process Description: This process uses the function of anion and cation resin to exchange and remove ions in the syrup liquid for the process of making corn starch syrup, and the resin also has the function of adsorbing color and macromolecule. Through this process, the effect of removing ions and color in the product is achieved.

-B. Process parameters:

a. The syrup liquid feed temperature is strictly controlled at <45 ° C;

b. Maintain flow rate <4m/h.

-C. Quality requirements:

a. pH value of 3.5-6.0, the liquid syrup is clear and transparent;

b. Sugar solution (20%), conductivity <50us/cm.

Corn starch syrup processing factory

Corn starch syrup processing factory

7. Three-effect vacuum concentration

-A. Process description: Maintain a certain degree of vacuum in the evaporation chamber to lower the boiling point, so that the sugar liquid evaporates water at a relatively low temperature to achieve the purpose of concentration.

-B. Process parameters:

a. Vacuum degree: one effect ≥ 0.02Mpa; two effect ≥ 0.04Mpa; three effects ≥ 0.07Mpa.

b. Temperature: one effect ≥ 90 ° C; two effect ≥ 70 ° C; three effect ≥ 50 ° C.

-C. Quality requirements:

a. PH value 4.0-6.0.

b. Solids >70% or implement customer standards.

c. The produced corn starch syrup is colorless and transparent, and has no odor.

Produced corn starch syrup

Produced corn starch syrup

Doing Company corn starch syrup making process produced is a colorless, transparent and viscous liquid syrup prepared by high quality corn starch. The corn starch syrup product is clear, transparent, mild and pure, and low in sweetness. Corn starch syrup has a malt flavor and has many advantages such as high cooking temperature, low freezing point and anti-crystallization. It is often used in jams and jellies to prevent crystal precipitation of sugar. High malt has good expandability, so it is also widely used in the production of bread, cakes and beer, it is also widely used in the fields of candy, beverages, preserved foods, frozen foods, condiments and the like. In addition, corn starch syrup does not depend on human islet metabolism, blood sugar rises slowly, and calorie is low, and it has certain health care functions for cardiovascular patients, diabetics and obese people.

Finally, to sum up, the main corn starch syrup processing equipment from Doing Company include: mixing tank, ejector, liquefaction tank, saccharification tank, plate frame filter press machine, ion exchange column, decolorization tank, syrup evaporator, syrup storage tank, etc. For the process of making corn starch syrup, any questions, just contact us freely.