How making glucose syrup ?

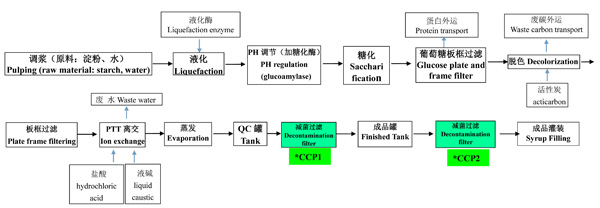

2018-12-05 / FAQIn brief, about how making glucose syrup, Doing Company offered glucose syrup production processing are: Raw material → pulping → soaking → standardization → first jet liquefaction, flashing, heat preservation → second jet liquefaction → dextrinization, cooling → saccharification → enzyme cooling, condensation and decontamination → filtration → first decolorization → Filtration→preconcentration→second decolorization→fine filtration→adsorption, ion exchange→finished syrup concentration

Glucose syrup making process

Glucose syrup making process

Below is the glucose syrup main making process details introduction:

1. Raw material preparation(starch / rice power):

Material quality requests: contain starch (dry basis) ≥ 80%, water content ≤ 14%, no putrefaction, high quality.

2. Pilping and liquefaction: Mixing starch with water, then adjust the concentration to 18Be, PH value 5.6-6.0, then add high temperature α-amylase, send it to the jet liquefier and steam to 100~108°C for liquefaction of starch to making glucose syrup. This glucose syrup making process adopt equipments are mixing tank, jet cooker and liquefaction tank.

Liquefaction equipment

Liquefaction equipment

3. Protein filtration:

The liquefied hydrolyzed dextrin solution (about 20 DE value) is sent to the plate and frame filter for protein separation and filtration, and the separated protein after washed, dried, pulverized and sieved, get protein cake, then packaging and storage, protein cake is a good animal feed, this process part to making glucose syrup can get a good add-value for your glucose syrup production factory. 4. Saccharification:

The dextrin hydrolyzate after separating the protein is sent to a saccharification tank for saccharification process. At this time, the temperature was adjusted to 60 ° C, and the pH was about 4.2 to 4.8, and a certain amount of saccharification enzyme was added for about 36 to 50 hours. Although the enzyme method for glucose syrup making process time cost is a little large, but syrup obtained by enzymatic hydrolysis is pure, light in color, has no bitter taste, and has high quality, which is beneficial to the full utilization of syrup liquid.

Saccharification tank

Saccharification tank

5. Decolorization:

The saccharification solution with the DE value of 97 or higher is heated to 75 ° C, and the activated carbon is added to the activated carbon for adsorption treatment for 0.5 to 1 hour, and then sent to a plate and frame filter for decarbonization and decolorization. Light rate should be ≥95% 6. Ion exchange:

The decolorized solution is cooled to 40-45 ° C and sent to an ion exchange column for anion-cation exchange for glucose syrup making, and the conductivity of the solution is less than 20 ppm.

7. Evaporation: The syrup liquid is evaporated to 77.5 Bx, which is the finished glucose syrup.

8. Storage and filling: The syrup is sent to the finished product tank for storage, and if necessary, it is pumped into the filling tank and quantitatively loaded into the packaging container.