Process to make high fructose corn syrup

2018-07-30 / FAQ

The technology of the process to make high fructose corn syrup:

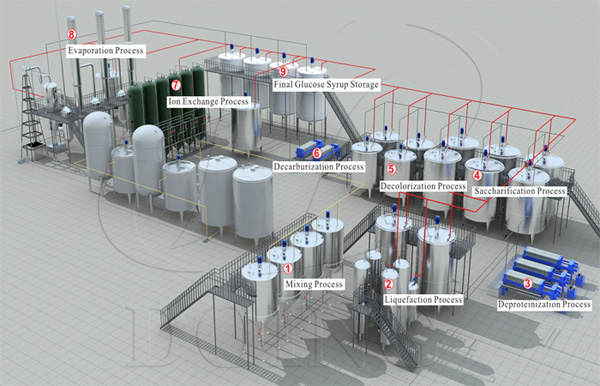

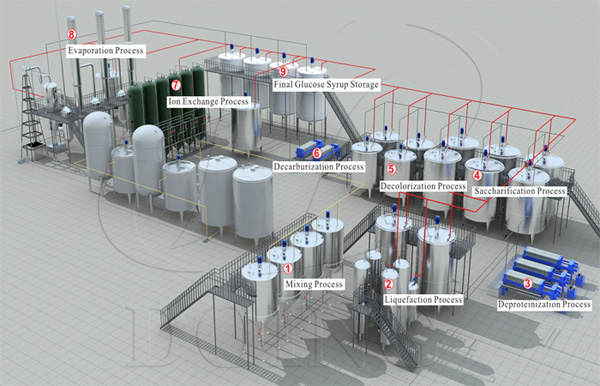

We use the newest technology for high fructose corn syrup process, maize/corn as raw material, no need convert starch firslty, just make corn into corn flour, and then use corn flour to convert syrup, and different enzyme adopted can produce different type syrup, firstly get the glucose from corn flour then transfer the syrup into high fructose corn syrup in the process to make high fructose corn syrup. By the way, use the corn starch to process syrup, its effect and syrup quality is better than use corn flour. Doing Company have built several projects for syrup process in China and all over the world. The process to make high fructose corn syrup can be divided into several parts as below:

High fructose corn syrup process

1.Continuous jet liquefaction section process:

(1) Mixing slurry: Add thermostable amylase and water to flour, and mix them in specialize mixing tank.

(2) Jet liquefaction: Heating all tanks by steam, then start liquid ejectors and pumps. Delivery material continuously and evenly, and control flow by production capacity. Flash evaporate material in Laminar flow tank, and keep temperature. Observe liquefaction effect.

(3) High temperature treatment: Send passed material to the second Liquid ejector, and keep temperature.

(4) Carry slurry to buffer tank by pump in the process to make high fructose corn syrup.

Jet liquefaction machine

2.Filtration section in the process to make high fructose corn syrup:

(1) Filter protein and slag by plate-and-frame filter press machine.

(2) Carry away protein and slag by bottom slot in plate-and-frame filter press machine.

(3) Syrup inflow buffer tanks, then be sent to next step by pump in the process to make high fructose corn syrup.

Plate frame filter press machine

3.Saccharification section:

Cooling syrup by heat-exchanger, then send them to saccharification tank (mixer and coil pipe are set in saccharification tank. ) by pumps, then add glucoamylase for material saccharification to get glucose.

4.Decolorization in the process to make high fructose corn syrup:

Carry passed syrup into decolorization tanks(mixer and coil pipe are set in saccharification tank.) by pump. Decolor by activated carbon

Saccharification tank

5.Second filtration section:

(1) Filter activated carbon by plate-and-frame filter press machine.

(2) Carry away waste activated carbon in plate-and-frame filter press machine

(3) Unclean syrup is sent to big buffer tanks by pump.

(4) Carry clean syrup into buffer tanks in the process to make high fructose corn syrup.

Ion exchange column

6.Ion exchange of the process to make high fructose corn syrup:

(1) Carry syrup into ion exchange columns. Resin clean syrup in ion exchange columns. Then carry clean glucose syrup into buffer tanks.

(2) When resin loses effect, stop carry syrup into ion exchange columns, and change another ion exchange column for process to make high fructose corn syrup.

(3) Recover resin: Using heat water to bush resin, then use acid fluid, and alkali fluid to bush ion exchange columns till resin has function.

Isomerism

7.Isomerism system to transfer glucose into fructose:

The isomerase we are using is a kind of immobilized enzyme. Converted from soluble state into immobilized state, the stability of isomerism will be increased significantly and it can be ues repeatedly in the process to make high fructose corn syrup. This immobilized enzyme used in food processing make food free of enzyme after production, so there is no need to adopt the way of heat treatment to make enzyme inactivated, which can help improving the quality of high fructose corn syrup as well as economic benefits.

Finished syrup

8.Evaporation:

Evaporate syrup by triple-concentrate of evaporator and single-concentrate of evaporator. When high fructose corn syrup concentration is OK, shut down steam and stop evaporation. And carry syrup to final product storage tanks by pumps.

All in all, among is our company brief answer for the process to make high fructose corn syrup, if you plan to install a high fructose corn syrup factory, welcome to contact us, if you have any questions of high fructose corn syrup production, our engineers will answer for you and give you a feasibility program according to your demand.

We use the newest technology for high fructose corn syrup process, maize/corn as raw material, no need convert starch firslty, just make corn into corn flour, and then use corn flour to convert syrup, and different enzyme adopted can produce different type syrup, firstly get the glucose from corn flour then transfer the syrup into high fructose corn syrup in the process to make high fructose corn syrup. By the way, use the corn starch to process syrup, its effect and syrup quality is better than use corn flour. Doing Company have built several projects for syrup process in China and all over the world. The process to make high fructose corn syrup can be divided into several parts as below:

High fructose corn syrup process

(1) Mixing slurry: Add thermostable amylase and water to flour, and mix them in specialize mixing tank.

(2) Jet liquefaction: Heating all tanks by steam, then start liquid ejectors and pumps. Delivery material continuously and evenly, and control flow by production capacity. Flash evaporate material in Laminar flow tank, and keep temperature. Observe liquefaction effect.

(3) High temperature treatment: Send passed material to the second Liquid ejector, and keep temperature.

(4) Carry slurry to buffer tank by pump in the process to make high fructose corn syrup.

Jet liquefaction machine

(1) Filter protein and slag by plate-and-frame filter press machine.

(2) Carry away protein and slag by bottom slot in plate-and-frame filter press machine.

(3) Syrup inflow buffer tanks, then be sent to next step by pump in the process to make high fructose corn syrup.

Plate frame filter press machine

Cooling syrup by heat-exchanger, then send them to saccharification tank (mixer and coil pipe are set in saccharification tank. ) by pumps, then add glucoamylase for material saccharification to get glucose.

4.Decolorization in the process to make high fructose corn syrup:

Carry passed syrup into decolorization tanks(mixer and coil pipe are set in saccharification tank.) by pump. Decolor by activated carbon

Saccharification tank

(1) Filter activated carbon by plate-and-frame filter press machine.

(2) Carry away waste activated carbon in plate-and-frame filter press machine

(3) Unclean syrup is sent to big buffer tanks by pump.

(4) Carry clean syrup into buffer tanks in the process to make high fructose corn syrup.

Ion exchange column

(1) Carry syrup into ion exchange columns. Resin clean syrup in ion exchange columns. Then carry clean glucose syrup into buffer tanks.

(2) When resin loses effect, stop carry syrup into ion exchange columns, and change another ion exchange column for process to make high fructose corn syrup.

(3) Recover resin: Using heat water to bush resin, then use acid fluid, and alkali fluid to bush ion exchange columns till resin has function.

Isomerism

The isomerase we are using is a kind of immobilized enzyme. Converted from soluble state into immobilized state, the stability of isomerism will be increased significantly and it can be ues repeatedly in the process to make high fructose corn syrup. This immobilized enzyme used in food processing make food free of enzyme after production, so there is no need to adopt the way of heat treatment to make enzyme inactivated, which can help improving the quality of high fructose corn syrup as well as economic benefits.

Finished syrup

Evaporate syrup by triple-concentrate of evaporator and single-concentrate of evaporator. When high fructose corn syrup concentration is OK, shut down steam and stop evaporation. And carry syrup to final product storage tanks by pumps.

All in all, among is our company brief answer for the process to make high fructose corn syrup, if you plan to install a high fructose corn syrup factory, welcome to contact us, if you have any questions of high fructose corn syrup production, our engineers will answer for you and give you a feasibility program according to your demand.