Preparation of glucose from starch

2018-05-17 / Processing

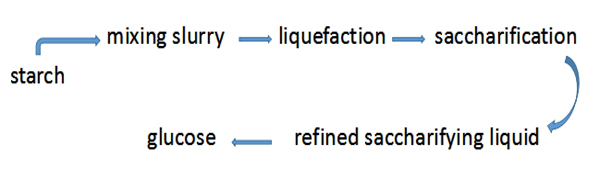

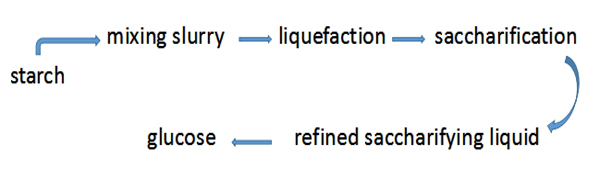

Preparation of glucose from starch is used starch as raw material, adopt double-enzyme method to prepare glucose. Nowdays, from starch prepared glucose has been widely substitute the sugar in the industrial production and family cooking. Use enzyme method for the preparation of glucose from starch is feasible and simple process. For another, the raw material for glucose preparation also can be other grains, you can click this raw material to manufacturer glucose to learn more. Its technical process as below:

Preparation of glucose from starch technical process

Doing Company can manufacturered all equipments and offer the technology of the preparation of glucose from starch, contain mixing tank, saccharify tank, ejector, ion exchange column, plate and frame filter press, evaporator, etc. Follwoing is the equipments photo:

Syrup equipments

The details technical process of the preparation of glucose from starch is:

1. Mixing slurry:

Mix the starch with water as the suitable percentage to get starch slurry. Add sodium carbonate solution and α-enzyme adjust the starch slurry PH value to 6.0-6.5, to keep the catalytic activity of the α-enzyme, use the calcium chloride as protectant and activator for enzyme, per kg starch demand 500mg calcium chloride and 5-10mg sodium chloride.

2. Liquefaction:

Mixed heat-stable α-enzyme (Novo’s Termamyl 120L) into the starch slurry, the slurry is instantaneously heated to 100 ℃ and held at this temperature for 10 min before it is cooled to 90 ℃. This temperature is maintained for 40-60 min, after this, boil for 10 min for sterilization and destroy the enzyme activity. For the preparation of glucose from starch, liquefaction process directly decided the yield, you also can understand this as the starch using rate of the preparation of glucose from starch.

Liquefaction process technical parameters:

3. Saccharification:

After liquefaction liquid cooled, use the dilute hydrochloric acid or dilute sulfuric acid adjust the pH value to 4.2-4.6, after the solution is cooled to 60 ℃. Added the glucomylase (Novo’s AMG 300L) immediately. The reaction time for saccharification is usually between 24-48 hour depending on enzyme reaction speed. After this, also boil the liquid to 100℃ to remove the enzyme. This section is important for the preparation of glucose from starch, and our saccharification liquid yield is about 98%-105%.

Doing Company-factory

Saccharification process technical paramters:

4. Refined saccharifying liquid:

Adopt the plate and frame filter press to filter the visible insoluble impurities out, then use the ion exchange column to remove ash, colored matter and organic impurity from the glucose solution. This refine process for the preparation of glucose from starch also contain the concentration section which adopt the evaporator to make the glucose reach a requests concentration, Doing Company will suggest you a most suitable evaporator for you in the light of your requests.

Finally, the professionl syrup storage tank also essential for the preparation of glucose from starch, its convinence for the shippment and package, and this storage tant select mainly according to the capacity in your glucose preparation factory. Here show our suggestions for you to construct your glucose preparation factory. Above all, this is Doing Company preparation of glucose from starch technology and equipments introduction.

Preparation of glucose from starch technical process

Doing Company can manufacturered all equipments and offer the technology of the preparation of glucose from starch, contain mixing tank, saccharify tank, ejector, ion exchange column, plate and frame filter press, evaporator, etc. Follwoing is the equipments photo:

Syrup equipments

1. Mixing slurry:

Mix the starch with water as the suitable percentage to get starch slurry. Add sodium carbonate solution and α-enzyme adjust the starch slurry PH value to 6.0-6.5, to keep the catalytic activity of the α-enzyme, use the calcium chloride as protectant and activator for enzyme, per kg starch demand 500mg calcium chloride and 5-10mg sodium chloride.

2. Liquefaction:

Mixed heat-stable α-enzyme (Novo’s Termamyl 120L) into the starch slurry, the slurry is instantaneously heated to 100 ℃ and held at this temperature for 10 min before it is cooled to 90 ℃. This temperature is maintained for 40-60 min, after this, boil for 10 min for sterilization and destroy the enzyme activity. For the preparation of glucose from starch, liquefaction process directly decided the yield, you also can understand this as the starch using rate of the preparation of glucose from starch.

Liquefaction process technical parameters:

| Starch slurry concentration | α-enzyme | PH value | Temperature | DE value |

| 32%-36% | 8-10g per ton dry starch |

before:6.0-6.4 after: 4.2-4.5 |

different value in different section | 15%-20% |

3. Saccharification:

After liquefaction liquid cooled, use the dilute hydrochloric acid or dilute sulfuric acid adjust the pH value to 4.2-4.6, after the solution is cooled to 60 ℃. Added the glucomylase (Novo’s AMG 300L) immediately. The reaction time for saccharification is usually between 24-48 hour depending on enzyme reaction speed. After this, also boil the liquid to 100℃ to remove the enzyme. This section is important for the preparation of glucose from starch, and our saccharification liquid yield is about 98%-105%.

Doing Company-factory

Saccharification process technical paramters:

| Glucomylase | PH value | DE value | Time cost | Saccharification liquid yield |

| 0.45-0.58L per ton dry starch | 5.5 | 95%-98% | 50h per tank | 98%-105% |

4. Refined saccharifying liquid:

Adopt the plate and frame filter press to filter the visible insoluble impurities out, then use the ion exchange column to remove ash, colored matter and organic impurity from the glucose solution. This refine process for the preparation of glucose from starch also contain the concentration section which adopt the evaporator to make the glucose reach a requests concentration, Doing Company will suggest you a most suitable evaporator for you in the light of your requests.

Finally, the professionl syrup storage tank also essential for the preparation of glucose from starch, its convinence for the shippment and package, and this storage tant select mainly according to the capacity in your glucose preparation factory. Here show our suggestions for you to construct your glucose preparation factory. Above all, this is Doing Company preparation of glucose from starch technology and equipments introduction.