Corn syrup production plant

For a completed corn syrup production plant, It is finished by many different steps, If you use corn as raw material, then you need make corn starch firstly. If you already have the corn starch, it will be much easier. Below is the corn syrup production plant processing steps:

1.Corn starch mixing section

Corn starch is mixed with warm water. PH is adjusted 5.0-6.0. keep 30-40mints ensure the enough mixting.

2. Continuous spray liquefaction section in corn syrup production plant

Spray liquefaction: Heating all tanks by steam, then start Liquid ejectors and pumps. Delivery material continuously and evenly, and control flow by production capacity.Flash evaporate material in Laminar flow tank, and keep temperature. Observe liquefaction effect. Then send passed material to the second Liquid ejector, and keep temperature.

Main corn syrup production machine

3.Filtration section

Remove some corn gluten by filter press.

4.Saccharification section

Cooling syrup by Heat-exchanger, then send them to Saccharification tank (mixer and coil pipe are set in Saccharification tank) by pumps in corn syrup production plant, then add glucoamylase.

5.Decolorization section:

Carry passed syrup into decolorization tanks(mixer and coil pipe are set in saccharification tank) by pump. Decolor by active carbon in corn syrup production plant.

Plate frame filter press machine

6.Filtration section:

(1).Filter protein and Activated carbon by Plate-and-frame filter press machine.

(2).Carry away protein by Bottom slot for Plate-and-frame filter press machine

(3).Unclean syrup is sent to big buffer tanks by pump.

(4).Carry clean syrup into buffer tanks.

Among is the several process section in corn syrup production plant filtration section.

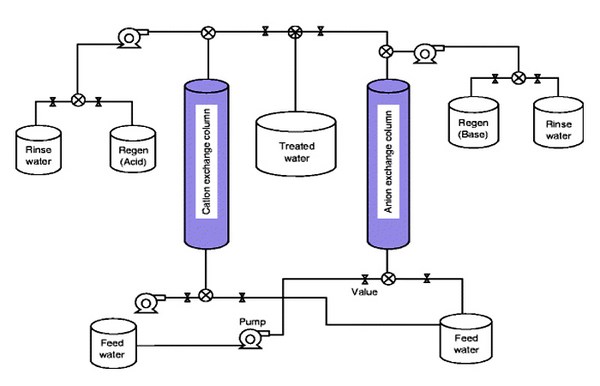

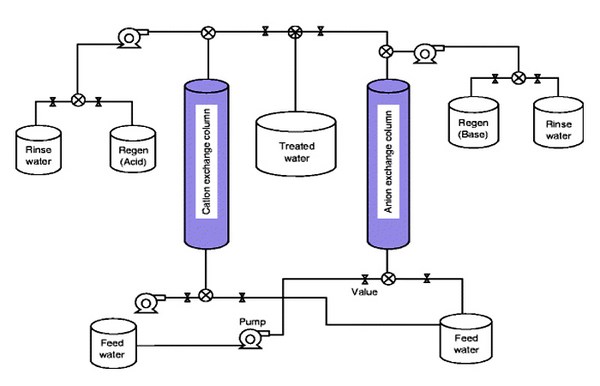

Ion exchange column working principle

7. Ion exchange section

(1).Carry syrup into Ion exchange columns. Resin clean syrup in Ion exchange columns. Then carry clean syrup into buffer tanks.

(2).When Resin loses effect, stop carry syrup into Ion exchange columns, and change another Ion exchange column for work.

(3).Recover Resin: Using heat water to bush resin, then use acid fluid, and alkali fluid to bush Ion exchange columns till Resin has function.

Corn syrup production plant overview

8.Evaporation process in corn syrup production plant

Evaporate syrup by Triple-concentrate of syrup evaporator and Single-concentrate of evaporator. When syrup concentration is OK, shut down steam and stop evaporation. And carry syrup to Final-product storage tanks by Pumps.

9.Final corn syrup storage:

It is generally recommended to use plastic buckets to install syrup and sealed.

Below is the main corn syrup production machines:

Note: the accurate technical parameters confirmed by the final corn syrup production plant production solution.

All machines above are the function introduce of corn syrup production plant,with the development of morden technology,we can provide the advanced technology,that is converting the corn into the syrup directly.Then you can save many labour and cost.But it mainly used for the very small capacity.

1.Corn starch mixing section

Corn starch is mixed with warm water. PH is adjusted 5.0-6.0. keep 30-40mints ensure the enough mixting.

2. Continuous spray liquefaction section in corn syrup production plant

Spray liquefaction: Heating all tanks by steam, then start Liquid ejectors and pumps. Delivery material continuously and evenly, and control flow by production capacity.Flash evaporate material in Laminar flow tank, and keep temperature. Observe liquefaction effect. Then send passed material to the second Liquid ejector, and keep temperature.

Main corn syrup production machine

3.Filtration section

Remove some corn gluten by filter press.

4.Saccharification section

Cooling syrup by Heat-exchanger, then send them to Saccharification tank (mixer and coil pipe are set in Saccharification tank) by pumps in corn syrup production plant, then add glucoamylase.

5.Decolorization section:

Carry passed syrup into decolorization tanks(mixer and coil pipe are set in saccharification tank) by pump. Decolor by active carbon in corn syrup production plant.

Plate frame filter press machine

(1).Filter protein and Activated carbon by Plate-and-frame filter press machine.

(2).Carry away protein by Bottom slot for Plate-and-frame filter press machine

(3).Unclean syrup is sent to big buffer tanks by pump.

(4).Carry clean syrup into buffer tanks.

Among is the several process section in corn syrup production plant filtration section.

Ion exchange column working principle

7. Ion exchange section

(1).Carry syrup into Ion exchange columns. Resin clean syrup in Ion exchange columns. Then carry clean syrup into buffer tanks.

(2).When Resin loses effect, stop carry syrup into Ion exchange columns, and change another Ion exchange column for work.

(3).Recover Resin: Using heat water to bush resin, then use acid fluid, and alkali fluid to bush Ion exchange columns till Resin has function.

Corn syrup production plant overview

Evaporate syrup by Triple-concentrate of syrup evaporator and Single-concentrate of evaporator. When syrup concentration is OK, shut down steam and stop evaporation. And carry syrup to Final-product storage tanks by Pumps.

9.Final corn syrup storage:

It is generally recommended to use plastic buckets to install syrup and sealed.

Below is the main corn syrup production machines:

| Machine | Model/ Volume | Quantity |

| Mixing tank | volume 100L | 2 |

| Liquefaction tank | 24 m3 | 1 |

| Saccharification tank | 200 m3 | 3 |

| Ejector | power 504 kw | 2 |

| Ion exchange column | 14 | |

| Filter press | 5000L/H | 4 |

| Vacuum cooler | volumn 12 m3 | 1 |

| Liquid-vapor seperator | volumn 12 m3 | 1 |

| Syrup storage tank |

All machines above are the function introduce of corn syrup production plant,with the development of morden technology,we can provide the advanced technology,that is converting the corn into the syrup directly.Then you can save many labour and cost.But it mainly used for the very small capacity.