How to make rice syrup ?

2018-08-06 / FAQ

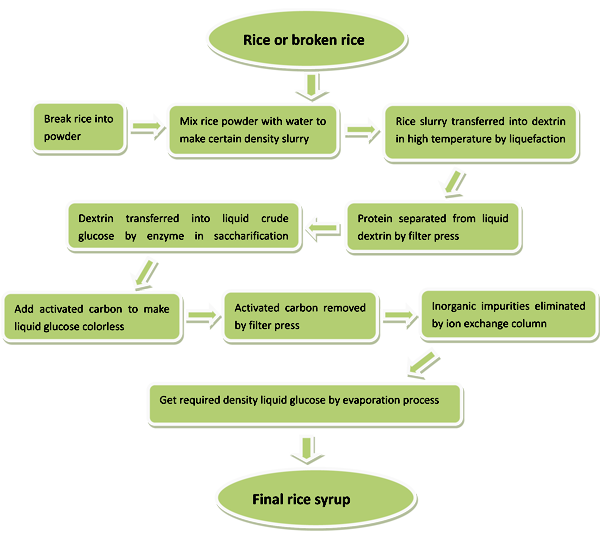

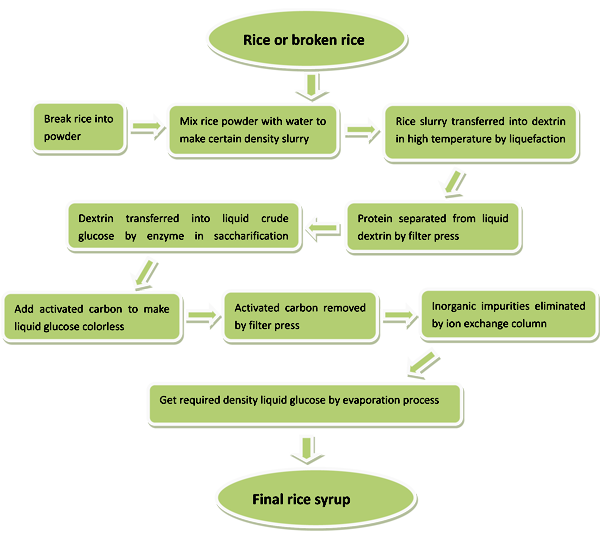

Rice is good as raw material for making glucose syrup. Full pieces of rice and broken rice can be used to make glucose. How to make rice syrup? Usually it can be divided into several procedures: Rice or broken rice→break rice into powder→mix rice powder with water to make certain density slurry→rice slurry transferred into dextrin in high temperature by liquefaction process→protein separated from liquid dextrin by filter press→dextrin transferred into liquid crude glucose by enzyme in saccharification process→add activated carbon to make liquid glucose colorless→activated carbon removed by filter press→inorganic impurities eliminated by ion exchange column→get required density liquid glucose by evaporation process→final rice syrup product.

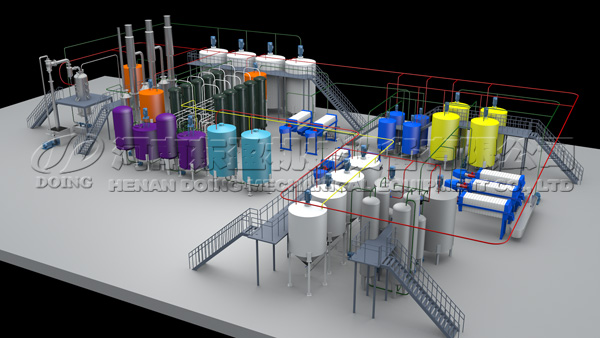

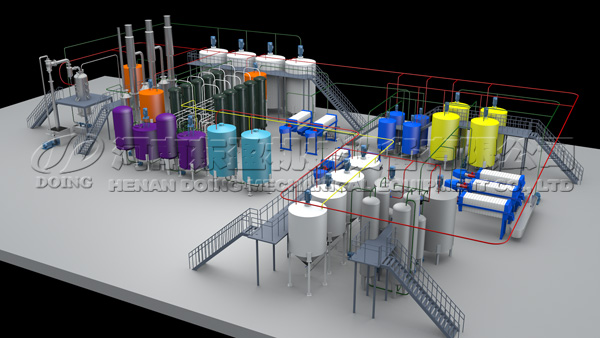

Rice syrup production machine

How to make rice syrup in high quality? There are three key points: high quality raw material, high working efficiency and good performance equipment, processing technology applied in glucose syrup production line. Glucose syrup making machine is not complicated and many manufacturers can supply the kind of machines. What mostly determines the final products is the processing technology.

Before rice syrup technology is put forward, people can only use starch as raw material to make glucose, which largely limit glucose industry development. In latest technology, how to make rice syrup directly from raw crops is overcome and come true.

Rice syrup production process

How to make rice syrup consists of six steps as bellow:

First step is grinding process and mixing process. Break rice into fine powder, then mix rice powder with water to get certain density rice slurry. Soften water is better because it can reduce ion impurities in later process. The mixing process will be finished in certain temperature and PE value.

Second step is liquefaction process. Rice slurry is transferred into liquefaction tank. Jet cooking makes temperature increase quickly in short time, resulting in starch granules absorb water quickly and expend together to get transparent paste liquid, which is called gelatinization. Gelatinization provide better condition for the later liquefaction process. After liquefaction process, we will get dextrin.

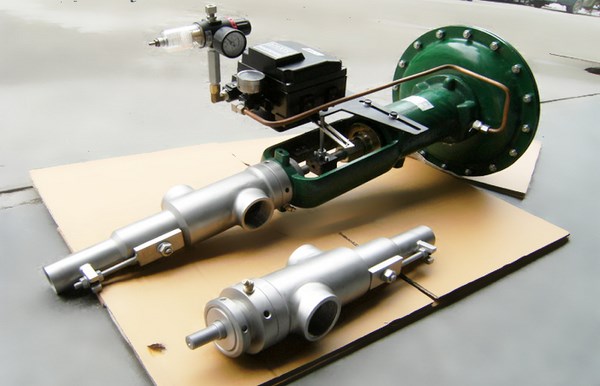

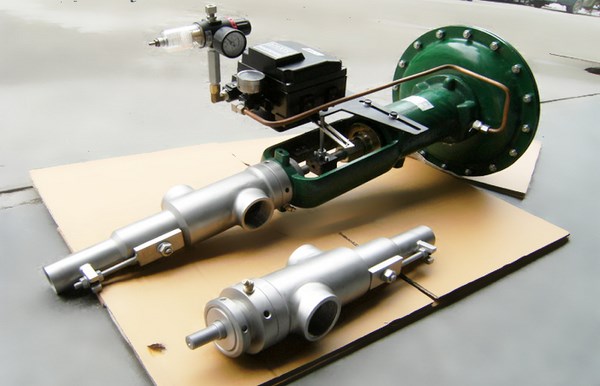

Jet cooking machine

Third step is saccharification process. It's the key process to how to make rice syrup as required, which directly determines DE value of final products. In fact, the saccharification process is to create an environment suitable for saccharification enzymes. The key point is pH and temperature adjustment. The final hydrolysis of the sugars gives a crude saccharification solution.

Fourth step is decolorization and decarburization process. The purpose of decolorization is to remove organic impurities dissolved in water and makes liquid glucose colorless. Add powdered activated carbon into liquid glucose, and activated carbon is insoluble in water, and then we can use filter press machine to finish decarburization process. The filter removes the activated carbon as well as removes organic impurities from the sugar solution.

Rice syrup filter press machine

Fifth step is ion exchange process. After the water-insoluble impurities and organic impurities in the sugar liquid are removed, there still contain many inorganic impurities dissolved in water. These impurities exist in the form of cations and anions in water. Water-soluble inorganic impurities could be eliminated by ion exchange column.

The last sixth step is evaporation process. After previous steps, impurities in the liquid glucose are mostly removed. The last step will use evaporator to remove excess water and get final rice syrup in certain density. Three-effect evaporator is commonly applied.

Rice syrup making machine design

To sum up, how to make rice syrup consists of four main parts: grinding and mixing, saccharification, impurities-removing and concentration.

Rice syrup production machine

Before rice syrup technology is put forward, people can only use starch as raw material to make glucose, which largely limit glucose industry development. In latest technology, how to make rice syrup directly from raw crops is overcome and come true.

Rice syrup production process

First step is grinding process and mixing process. Break rice into fine powder, then mix rice powder with water to get certain density rice slurry. Soften water is better because it can reduce ion impurities in later process. The mixing process will be finished in certain temperature and PE value.

Second step is liquefaction process. Rice slurry is transferred into liquefaction tank. Jet cooking makes temperature increase quickly in short time, resulting in starch granules absorb water quickly and expend together to get transparent paste liquid, which is called gelatinization. Gelatinization provide better condition for the later liquefaction process. After liquefaction process, we will get dextrin.

Jet cooking machine

Third step is saccharification process. It's the key process to how to make rice syrup as required, which directly determines DE value of final products. In fact, the saccharification process is to create an environment suitable for saccharification enzymes. The key point is pH and temperature adjustment. The final hydrolysis of the sugars gives a crude saccharification solution.

Fourth step is decolorization and decarburization process. The purpose of decolorization is to remove organic impurities dissolved in water and makes liquid glucose colorless. Add powdered activated carbon into liquid glucose, and activated carbon is insoluble in water, and then we can use filter press machine to finish decarburization process. The filter removes the activated carbon as well as removes organic impurities from the sugar solution.

Rice syrup filter press machine

The last sixth step is evaporation process. After previous steps, impurities in the liquid glucose are mostly removed. The last step will use evaporator to remove excess water and get final rice syrup in certain density. Three-effect evaporator is commonly applied.

Rice syrup making machine design

To sum up, how to make rice syrup consists of four main parts: grinding and mixing, saccharification, impurities-removing and concentration.